Factors for affecting the price of grey iron castings

As a common material for mechanical castings, grey iron castings are also more concerned about the price, so the price of grey iron castings is determined by various factors, and how to understand the price at the time of purchase?

1. Grey iron castings are smelted and cast from pig iron, and the market price of pig iron will be proportional to the price of grey iron castings. The price of pig iron can be queried through many channels, and the price of grey iron castings will fluctuate with the market price of pig iron.

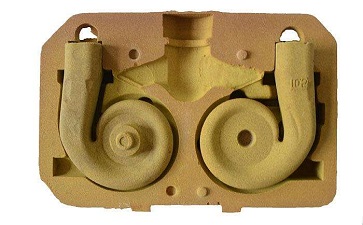

2. Different casting methods lead to different prices. The casting process includes several aspects such as casting mould, modelling process, heat treatment process, etc. Casting moulds are divided into wood type, aluminium type, sand shell type, foam type, etc., with the order of mould production price from high to low being sand shell type, aluminium type, wood type, foam type. The moulding process is divided into clay sand moulding, cement sand moulding, resin sand moulding, glass sand moulding, vacuum moulding, silica sol moulding, coated sand moulding, etc. The price of grey iron castings of the same material will vary due to different casting moulds or modelling processes, and the price of final castings will also differ.

3. An analysis of the relationship between casting material and price: Grey iron castings are made of HT150, HT200, HT250, HT300, HT350. The price of grey iron castings made from different materials will vary significantly, and the casting materials selected in different industries or application fields are also different.

4. An analysis of the relationship between the quality of castings and the price of grey iron castings: Ordinary grey iron castings, such as handwheels, non-load-bearing brackets, pulleys, cast iron radiators, counterweight cast iron, etc., have low quality requirements and relatively low prices. Key components used in mechanical parts are sometimes subjected to high pressure, high temperature, high torque, etc., so the performance requirements for castings are relatively high, leading to an increase in the relative price of castings.

5. In summary of the above aspects, it can be concluded that after determining the use of grey iron castings, selecting the appropriate casting process and mould (chosen according to the number of castings) and other conditions, and then combining this with the market price of pig iron at that time, a relatively reasonable price of grey iron castings can be obtained. Finally, synthesising the quotations of several grey iron casting manufacturers (the basis of the quotation is to unify the specific conditions and related parameters of grey iron castings) allows for an accurate grasp of the price of grey iron castings at that time.