How to Correctly Choose the Material for Gray Iron Castings

2025-09-05

When selecting the material for gray iron castings, it is important to understand in detail what performances can be achieved by different grades of gray iron. Then, compare them with the wall thickness of your product parts to see which grade of gray cast iron is suitable for your product.According to the specifications in GB/T9439-1988, the mechanical properties of each grade under different wall thicknesses are determined using a single casting test bar with a diameter of 30 millimeters. Gray cast iron is specifically divided into six grades: ferritic gray cast iron (HT100), ferritic pearlitic gray cast iron (HT150), pearlitic gray cast iron (HT200, HT250), and spheroidal graphite cast iron (HT300, HT350).

The tensile strength varies with different wall thicknesses of gray iron castings; this is a general condition. For the same grade of gray cast iron, the tensile strength also varies with the wall thickness.

HT100 gray cast iron has a lower tensile strength and is generally used for non-critical components with low load and friction, such as end covers, handles, brackets, and protective covers in smaller castings. The tensile strength requirement for this type of casting is relatively low, ranging between 80-130 σb/Mpa.

HT150 gray iron castings are generally used for components with a certain load-bearing capacity, such as brackets, bearing seats, pump bodies, valve bodies, motor bases, workbench, pulleys, and other mechanical components. The load capacity, converted to tensile strength, ranges from 120-175 σb/Mpa.

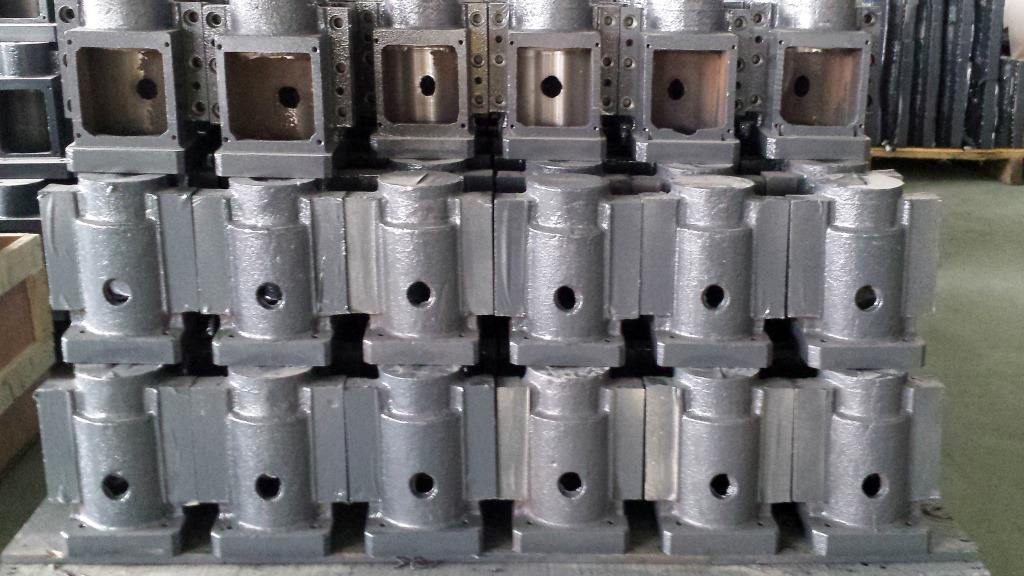

HT200-HT250 gray iron has certain sealing and corrosion resistance capabilities while also bearing a larger load than HT150 material gray iron. It is used in various gears, cylinders, housings, low-pressure valve bodies, flywheels, and machine tool beds. The tensile strength for this grade ranges between 160-270 σb/Mpa.

HT300-HT350 belongs to spheroidal graphite cast iron and is characterized by high load-bearing capacity, wear resistance, and good sealing performance. Examples include heavy machine tool components, press castings, high-pressure hydraulic parts, heavy-duty equipment gears, cams, and other mechanical castings. The mechanical properties have a tensile strength value ranging from 230-340 σb/Mpa.Therefore, it is essential to determine the correct material for parts during the initial design of gray iron castings to achieve the desired design values.