Key Technologies for the Pouring Process of Gray Iron Castings

2025-11-03

In the foundry industry, there is a saying of 'three goods,' which refers to good molten iron, good molding sand, and good technology.

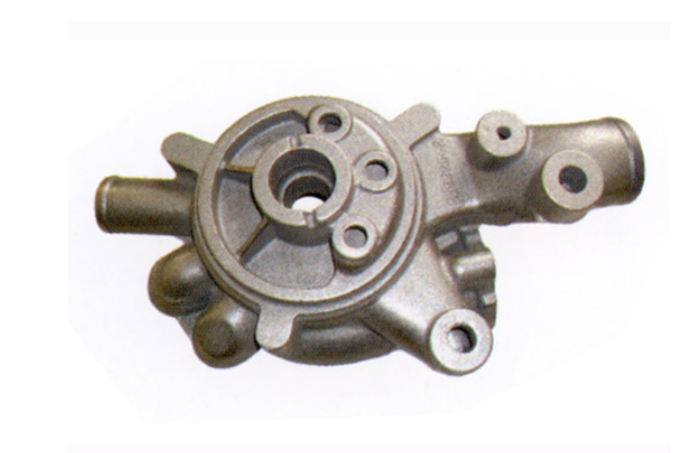

Foundry technology, together with molten iron and molding sand, is one of the three key elements in manufacturing castings. In sand molds, a mold is made using a pattern, allowing molten iron to flow into the mold cavity for casting.

The process of gray iron castings involves researching and determining the flow paths and methods.Mold components for gray iron castings include:Pouring gate: This is where molten iron is poured from the ladle into the mold entrance.

To ensure uniform pouring and remove inclusions in molten iron, a slag cup is often set up. Below the slag cup is the pouring gate.Runner: Refers to the horizontal section where molten iron flows from the main runner to the mold cavity.Inner gate: The location where molten iron enters the mold cavity from the runner. As the casting saying goes, the 'weir' is an essential part of the process.Vents: Channels for discharging air from the mold cavity as it fills with molten iron.

They are generally unnecessary if the molding sand has suitable permeability.Risers: Used to remove inclusions in the molten iron and impurities in the mold. Due to shrinkage during cooling of gray iron castings, risers are often not sufficient in volume. When acting as a feed, they are called feed risers, and these are quite thick.

The process for gray iron castings ensures smooth pouring and good casting quality. The pouring time should be as short as possible, and the mold cavity should be free of any turbulence. Key points are as follows:(1) Top and bottom of the mold: The parting surface of a gray iron casting should be as low as possible in the lower section of the mold, since the lower parts have fewer shrinkage cavities and denser material.(2) Pouring method: Top-pour for the upper section, bottom-pour for the middle and lower sections. Top-pour molds tend to cause sand defects and are less commonly used.(3) Position of inner gates: Because molten iron quickly solidifies upon entering the mold cavity, placing inner gates in thick-walled sections can prevent iron from reaching thin-walled parts. In large castings, if the inner gate is small, the molten iron flows quickly, potentially causing sand defects near the inner gate. The number and shape of inner gates should be considered when determining their position.(4) Types of inner gates: Mainly triangular and trapezoidal inner gates. Triangular inner gates are easier to make, while trapezoidal inner gates can prevent slag from entering the mold.(5) Cross-section ratio of straight, horizontal, and inner gates: If the straight gate is a, horizontal gate is B, and inner gate is C, the ratio is a ∶ B ∶ C = 3.6 ∶ 4 ∶ 2.0. Although there are different opinions on this ratio, the reasoning is that molten iron first enters a 3.6-sized entrance, flows through a 4.0-sized large runner, and then enters the inner gate. Due to the narrow 2.0-sized inner gate, the flow rate slows down over time, allowing lighter inclusions to rise and preventing them from entering the casting through the inner gate. This is the key point of the ratio. If this principle is remembered, exact details are not critical. Simply keep in mind that the design of the pouring system for medium, large, and small castings affects the physical properties and service life of gray iron castings.