Why are ductile iron parts galvanized on the surface?

2025-11-28

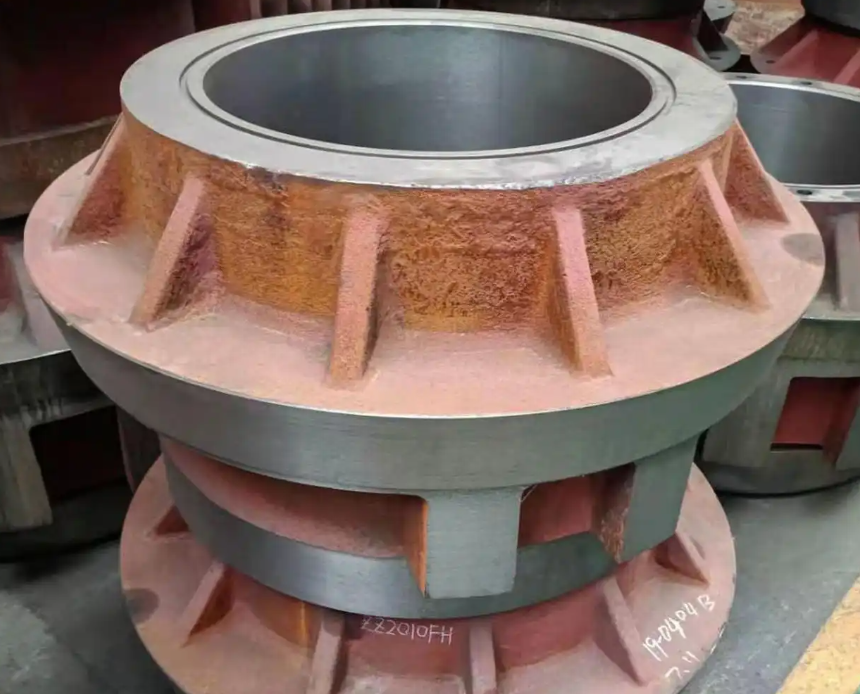

Ductile iron parts are widely used in many mechanical processing industries because their mechanical properties are superior to those of ordinary cast iron parts, and their various functions are close to those of carbon steel. With outstanding wear resistance, high damping capacity, low notch sensitivity, and excellent machinability, ductile iron holds an important position among cast irons. Many foundries apply galvanization to the surface of ductile iron during production; what is the reason for this?

The reason ductile iron parts are of higher quality than ordinary cast iron parts is mainly due to their strong compressive strength and excellent corrosion resistance, which is largely attributed to the galvanized layer on the surface of the ductile iron parts.

1. When the foundry galvanizes the surface of ductile iron, a chemical reaction occurs between the zinc and iron elements, forming a stable protective layer on the surface of the ductile iron part. This actively protects the product, preventing corrosion of the casting.

2. During contact with soil, the galvanized layer on ductile iron parts gradually transforms into a dense, adherent, continuous layer of zinc salts. This substance is not easily dissolved and can effectively protect the surface of the casting.

3. Galvanization on ductile iron parts can help create a self-repairing protective layer at damaged areas, ensuring the integrity of the workpiece.