What is Expansion Shell Rock Bolts?

Expansion Shell Rock Bolts are a type of mechanical rock reinforcement device widely used in underground engineering (such as mines, tunnels, and underground caverns) to stabilize fractured or loose rock masses.

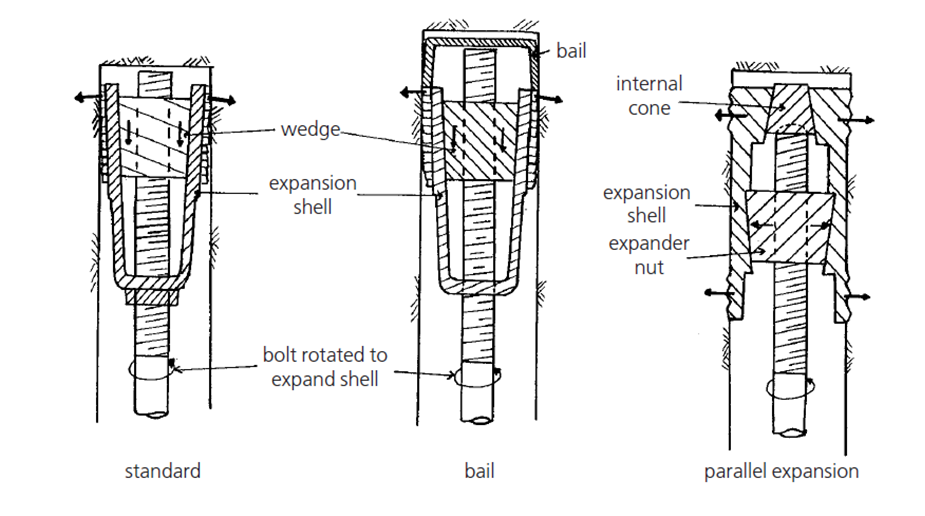

Core Working Principle

They rely on mechanical expansion to generate friction and clamping force between the bolt and the rock borehole. The key component is the expansion shell (a split, wedge-shaped sleeve) installed at the end of the bolt. When the bolt is tightened (usually with a nut on the exposed end), the expansion shell is compressed by a wedge, causing it to expand outward and press tightly against the inner wall of the borehole. This creates strong radial friction, anchoring the bolt firmly in the rock, and then the bolt can bear tensile loads to prevent rock collapse or displacement.

Basic Structure

Expansion shell assembly: The core anchoring part, consisting of a split steel sleeve and a matching wedge. The number of splits in the sleeve can be adjusted according to engineering needs.

Bolt body: A steel rod (usually threaded steel) that connects the expansion shell and the surface fixing component, and transmits the tensile force.

Surface fixing components: Including washers and nuts. Tightening the nut drives the wedge to compress the expansion shell, and the washer distributes the pressure evenly on the rock surface.

Key Characteristics

Rapid anchoring: The anchoring effect can be achieved immediately after tightening the nut, without waiting for grout curing (unlike grouted rock bolts), which is suitable for urgent support scenarios.

Mechanical anchoring: No need for grouting materials, which is convenient for construction in water-rich or low-temperature environments where grout is not easy to solidify.

Limited anchoring depth: The effective anchoring force mainly comes from the contact between the expansion shell and the borehole wall, so it is generally used as temporary or short-term support. For long-term and high-stability requirements, grouted rock bolts are more suitable.

Easy installation and removal: The operation process is simple, and it can be removed and reused if necessary (under the premise of ensuring structural safety).

Typical Application Scenarios

Temporary support in mine roadways and stope faces.

Emergency reinforcement of fractured rock sections during tunnel excavation.

Support for small-scale underground engineering with short service life.