How to Choose the Right Machining Process for Ductile Iron Castings?

2025-09-22

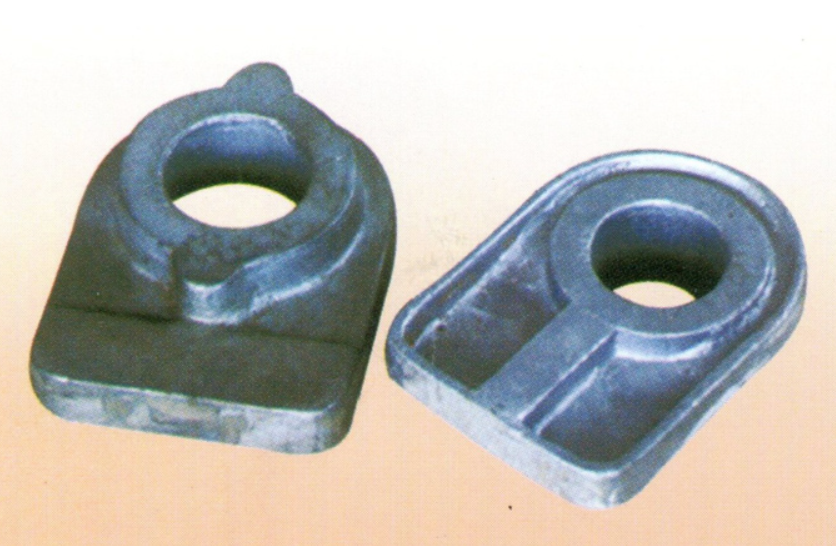

Ductile iron castings are widely used as a casting material due to their good mechanical properties and corrosion resistance, finding applications in mechanical manufacturing, the automotive industry, aerospace, and other fields. Selecting the appropriate processing technology for ductile iron castings is critical to ensuring their quality and efficiency.

This article will introduce how to choose the right processing technology for ductile iron castings.

1. Material Characteristics

Ductile iron castings have good toughness and strength, but they also have some characteristics, such as a tendency to develop pores and burrs, which need to be considered in terms of processing difficulty and specificity. When selecting a processing technology, it is necessary to choose a suitable process based on the characteristics of the ductile iron castings, such as milling, turning, drilling, etc.

2. Selection of Processing Technology

1. Milling is one of the more common processes in the machining of ductile iron castings, capable of processing flat and curved complex shapes well. However, since ductile iron castings are prone to defects such as pores and burrs, it is essential to use high-quality milling cutters and select appropriate cutting parameters based on the characteristics of the ductile iron castings to avoid issues like chip formation and scratches.2. TurningTurning is another commonly used process in the machining of ductile iron castings, suitable for processing round or arc-shaped parts. Because ductile iron castings have high hardness, it is essential to choose sturdy turning tools and carry out reasonable tool selection and cutting parameter design based on the characteristics of the ductile iron castings to ensure good machining results.3. DrillingDrilling is one of the common processes in the machining of ductile iron castings, applicable for processing small and deep holes. The characteristics of ductile iron castings require attention to the quality and smoothness of the hole walls. Therefore, when selecting drill bits, it is important to use high-quality bits and design reasonable cutting parameters based on the required hole diameter and depth.

3. Selection of Processing Equipment

When choosing processing technology for ductile iron castings, the selection of processing equipment is also crucial. The high hardness of ductile iron castings necessitates the use of processing equipment capable of withstanding heavy loads while ensuring precision and stability. Additionally, to guarantee processing efficiency and precision, it is essential to use compatible tools and fixtures as auxiliary processing equipment, making reasonable adjustments and operations based on the characteristics and requirements of the ductile iron castings.

4. Optimization of Processing Workflow

In addition to selecting suitable processing technologies and equipment, optimizing the processing workflow is key to improving the machining efficiency and quality of ductile iron castings. Throughout the processing, it is necessary to design a reasonable workflow and sequence based on the characteristics and requirements of the ductile iron castings to avoid redundant processing and waste while ensuring machining precision and stability.In conclusion, selecting the appropriate processing technology for ductile iron castings requires considering factors such as material characteristics, processing technology selection, equipment selection, and workflow optimization. Only by accounting for these factors and conducting reasonable processing operations and adjustments can the efficiency and quality of ductile iron casting machining be guaranteed.