Industry News

How to Choose the Right Machining Process for Ductile Iron Castings?

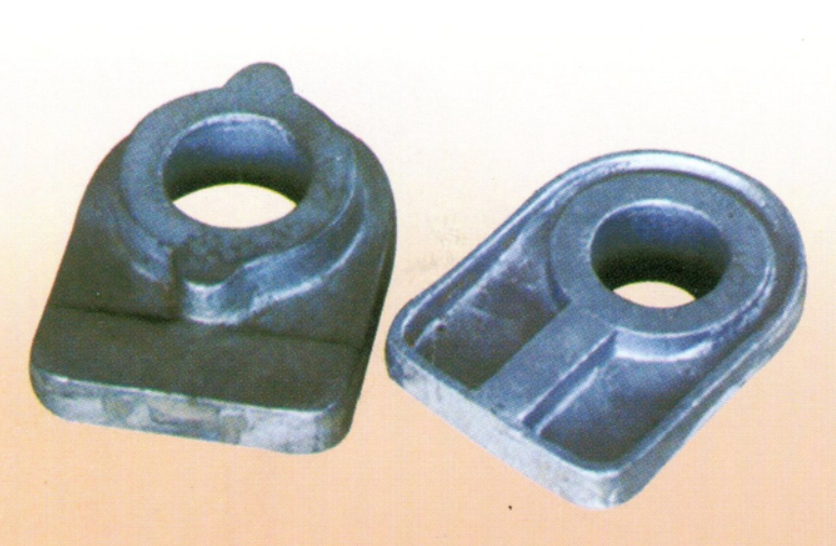

Ductile iron castings are widely used as a casting material due to their good mechanical properties and corrosion resistance, finding applications in mechanical manufacturing, the automotive industry, aerospace, and other fields. Selecting the appropriate processing technology for ductile iron casti......

Read MoreWhat is the carbon content of ductile iron castings?

What is the carbon content of ductile iron castings:Carbon is a fundamental element in ductile iron castings. A higher carbon content can promote the graphitization of the castings. Since graphite takes on a spherical shape, it can absorb energy in mechanical applications and thus improve the physic......

Read MoreTips for the production and processing of cast steel parts

Cast steel parts, as the name suggests, are components made by pouring molten steel. Compared to ordinary cast iron parts, cast steel parts have better strength and ductility. However, casting manufacturers often encounter various challenges during the production of cast steel parts. How should they......

Read MoreWhat are the advantages and acceptance standards of gray cast iron castings?

Gray iron castings use lost foam and resin sand casting processes, equipped with large gas tempering kilns, manual aging, and quenching to release internal stress, thereby improving the accuracy of the castings after processing. During the finishing process of the bed body, the machine tool experien......

Read MoreHow should the spots on the surface of ductile iron castings be removed?

Ductile iron castings are workpieces produced through ductile iron casting. These workpieces possess high strength that can rival even steel in terms of overall performance, and they can maintain high strength, toughness, and wear resistance even under complex stress conditions.

Read More